Robotic Process Automation, or RPA, enables automating processes. Much of the news regarding RPA revolves around automation, not processes. For example, we hear about the savings that are possible by automating tasks, the need to involve people in the move to automation, and ensuring that you build an effective automation program. In 2020, as RPA programs begin to grow and become more systematic, organizations need to spend more time on processes to achieve automation’s potential.

Why Processes?

The short answer is that processes deliver value to your customers. Streamlining a task—a part of a process—may have no impact on the actual throughput of a process. Instead, task automation may merely move the constraint from one part of the process to another. For example, in health care, an EHR may help with documenting care—a key part of the revenue cycle management process of a health care provider—but may also create data entry bottlenecks. In fact, RPA has explicitly been used to bridge the gap between systems to address these sorts of bottlenecks.

Yet task automation does deliver important early wins in your RPA initiative. Task automation can yield significant productivity gains. Eventually, however, it’s critical to move from automating tasks to automating processes to realize better results.

This post outlines three areas where process mapping should be employed for your RPA initiative.

1. Use Process Mapping to Prioritize Automation Efforts

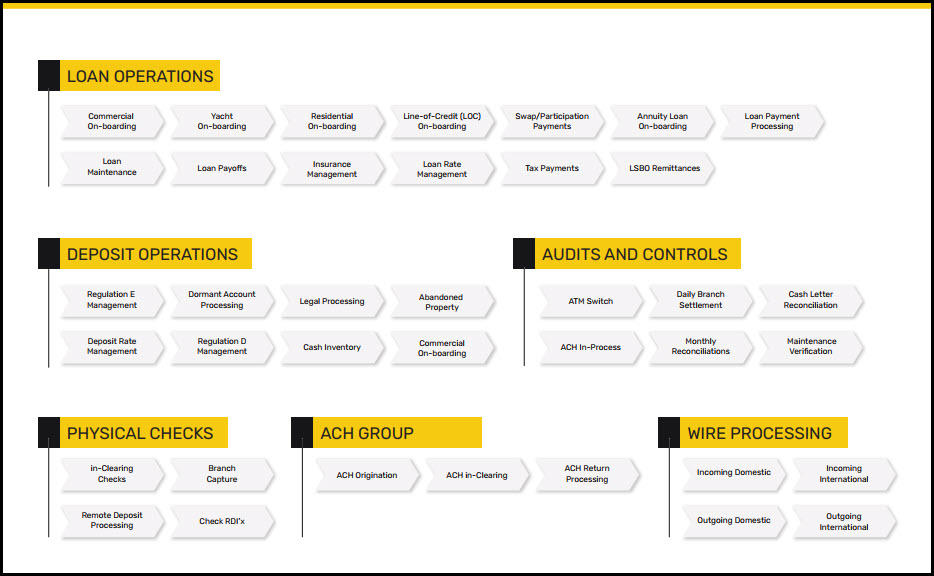

A value chain map, first used in lean manufacturing, provides a high-level view of a company’s flow of goods from inputs to customer. Conceptually, value chain maps have been adopted in other industries to understand the high-level processes that deliver value to the market. The following value chain map is representative of a bank which includes loan operations and deposit operations, for example, as core value-creation processes for customers.

Value chain maps help you to focus automation efforts on processes that matter most versus processes that are important but not as critical. In the sample map, all of the processes are critical. However, a more complete map may include non-core processes like HR or marketing functions. Again, these processes may be important, but a bank may find it’s acceptable for the recruiting process or the marketing planning process to experience an interruption for a few days or a week. If payments or deposits can’t be processed for a day, the bank would clearly suffer more.

Once a value chain map is created, you can chart a course for automation that balances risk and reward. As your initiative gains momentum, a value chain map helps to both track progress and establish a road map for what’s next.

2. Understand the “as-is” Process to Uncover What is Really Happening

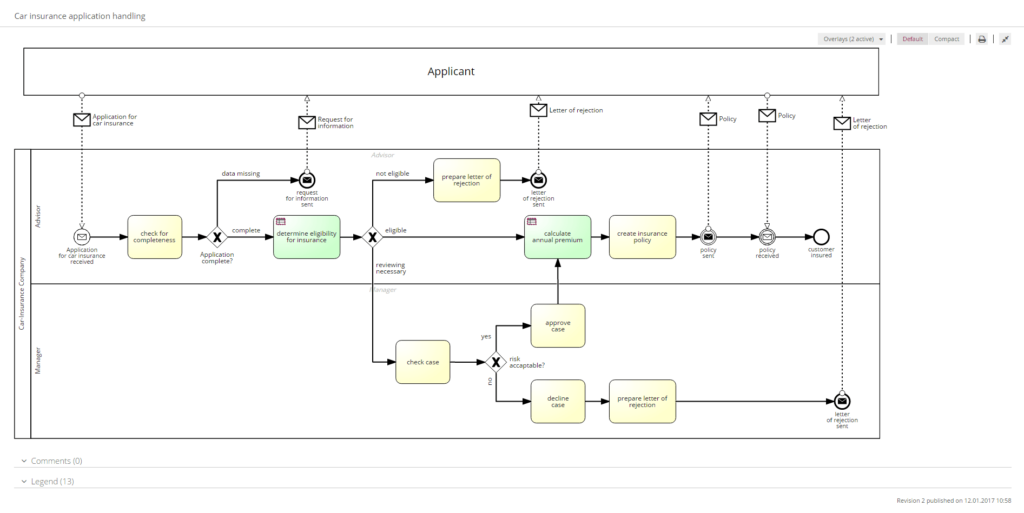

There are always surprises when an organization maps processes. Mapping the current set of steps, or the “as-is” process, exposes the fact that different people understand the same process differently. The people who perform some tasks know them well, but they may not know other tasks required for the overall process. Management may hold an ideal view of a process and may not realize that people perform manual steps that make the process work.

Process mapping uncovers what is really happening. A process map, like the one shown in the following image, outlines all of the steps, whether performed manually or with systems, to capture the actual sequence of activities. Of course, seeing what really happens provides opportunities to remove unnecessary steps. This understanding also helps to avoid errors in automation by ensuring that all necessary steps are performed.

3. Use Process Mining to Monitor and Improve Automated Processes

Process mapping has been used for decades to understand and improve processes. Process mapping vendors have added new capabilities that can also be used for an automation program.

One of these new capabilities is process mining. Gartner defines process mining as, “…a technique designed to discover, monitor and improve real processes (i.e., not assumed processes) by extracting readily available knowledge from the event logs of information systems.”

In other words, processes can be mapped automatically by using data from the systems that execute process steps themselves. Not only can process mining help with understanding the “as-is” process but also the “to-be” process once it has been automated—either fully or partially. Process mining helps you to monitor and assess improvement to help quantify progress.

In 2020, more organizations will begin RPA initiatives or grow existing automation initiatives as pilots develop into mature programs. In this environment, pragmatic tactics, like process mapping, will grow in importance.

For more information on building a successful automation initiative, see the Executive Guide on Automation (form completion required) or subscribe to the Automation Insider blog.